Production

Modern technology for CNC-milling and CNC-turning

For the production of CNC milled parts and CNC turned parts, we have a modern machine park with various DECKEL MAHO machines and two new Hermle C22 machines with placement robots. We work with the latest technologies and our employees receive ongoing training. Thanks to the seamless connection to our CAD/CAM system, we can produce prototype parts within hours and series parts with minimal retooling.

With eight different 5-sided machining centres, we have maximum flexibility and a large capacity that meets the highest demands for performance, accuracy and quality. Equipped with placement robots and pallet changers, we are also your specialist for series production. On our turning/milling centres, we produce parts that are completely machined from bars up to 100 mm in diameter.

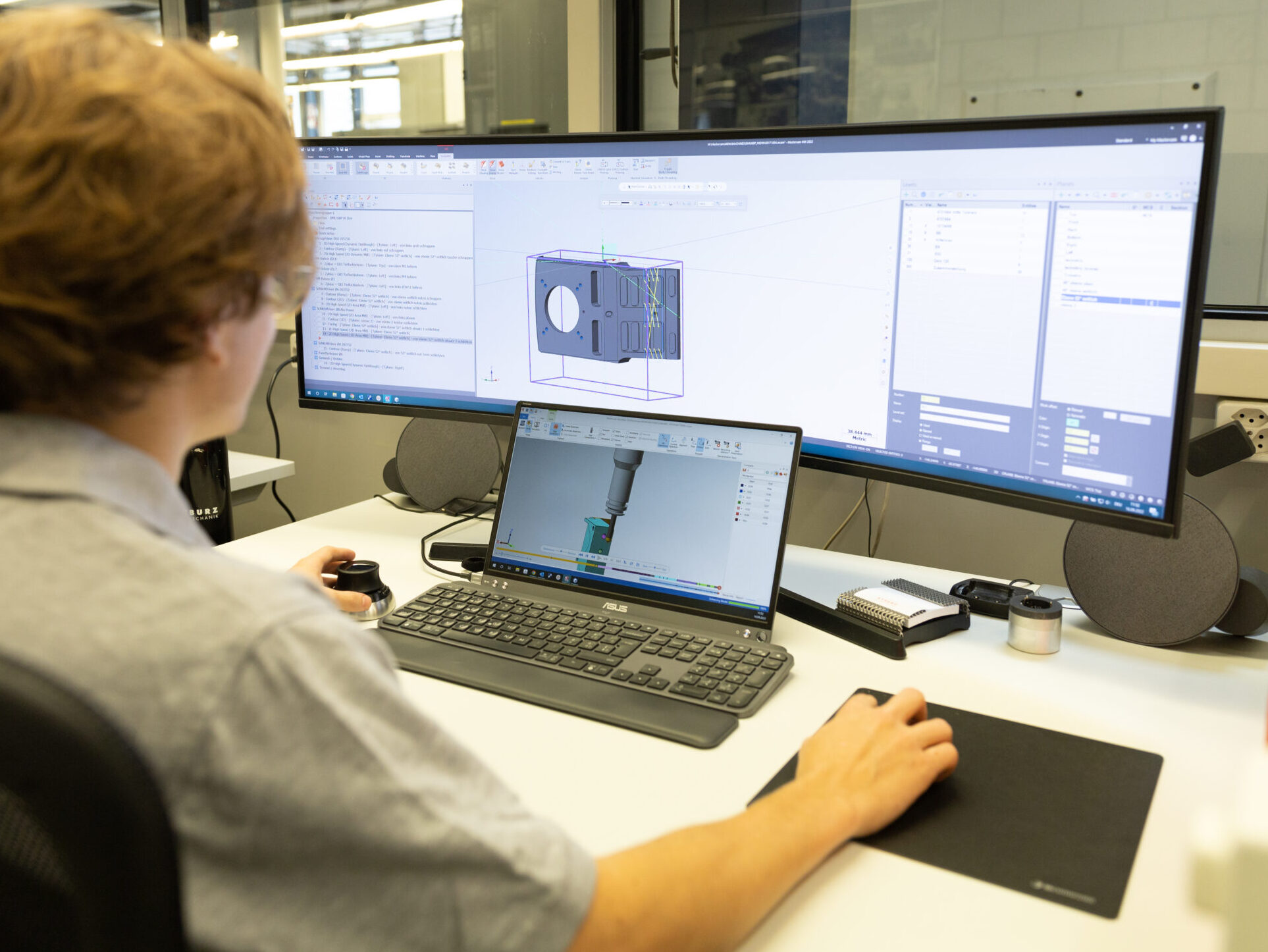

Programming

We program our machines on the Computer with Mastercam.

Mastercam Milling is a CAD/CAM system for milling up to five axes. The program is created on the computer using your drawing data (VDA-FS, IGES, SAT ACIS Solids, STL, DXF, CADL and ASCII).

CNC-milling

5-side processing with pick-and-place robot and pallet changer

Parts manufactured in one clamping are produced here with high precision, very quickly and therefore cost effective. Our eight milling centers with swivelling rotary table and swivel head are ideally suited for 5-sided machining of any workpiece and material.

CNC-turning

Turning and milling on one machine are no problem for our CNC-controlled turning centers! Vertically and horizontally driven tools and an automatic rod feed up to a diameter of 100mm save us many unnecessary clamping and save you high costs.

Batch sizes are getting smaller, delivery times shorter. Price pressure and the demands on the complexity and precision of the workpieces are also increasing. Our turning-milling-complete machining machines from DMG Mori are suitable for small and medium series.

Gildemeister CTX beta 1250 TC universale turning/milling machine

- complete machining from bar to 65mm diameter

- CNC control Siemens 840 D Powerline with Shop Turn

- tool magazine with 24 slots

- machining diameter up to approx. 250mm and approx. 500mm length

- with bar loader, counter spindle and NC-controlled B-axis

DMG Mori CTX beta 1250 TC 2nd turning/milling machine

- complete machining from rod to 100mm diameter

- CELOS CNC control with Siemens 840D sl Operate

- 80x tool chain magazine

- machining diameter up to approx. 300mm and approx. 500mm length

- with bar loader, counter spindle and NC-controlled B-axis

Drilling

Despite CNC controls, however, conventional drilling machines are indispensable. Our two Fehlmann stand drilling machines, all with precision coordinate table and digital display, are versatile and are well suited for accurate drilling and small milling operations.

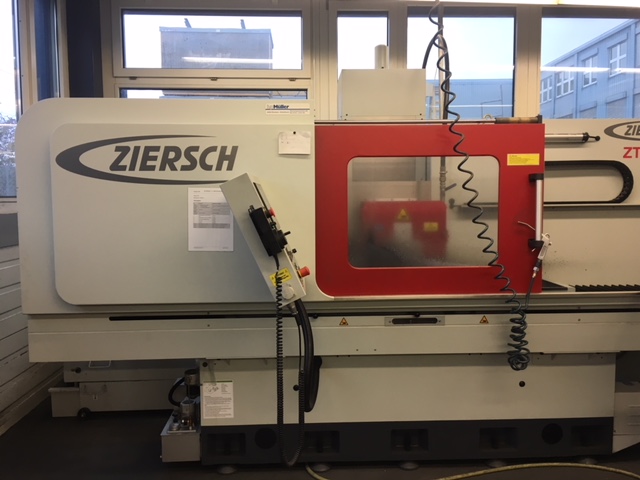

Grinding

We grind with a surface grinding machine Ziersch ZT48. The 2-axis control, an infinitely adjustable electromagnetic plate 400 x 800 mm and a Borazon disc allow us to grind even with hardened parts.

Laser engraving

Laser engraving is possible at any time. This means we can also laser mark the parts as required. Both individual components and large batch sizes can be labelled with laser marking for complete traceability, brand communication or functional markings.

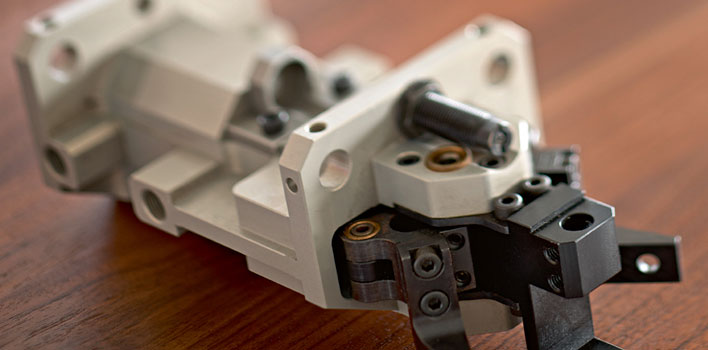

Assembling

Ready-to-assemble precision parts and assemblies

We offer our customers the entire technical process chain. From purchasing, production and assembly to surface finishing with reliable subcontractors. This applies to complex prototypes, individual parts, series and assemblies with high precision and consistent quality.