Production

Modern technology for CNC-milling and CNC-turning

We have state-of-the-art machinery at our disposal for the production of CNC milled parts and CNC turned parts. This includes various milling and turning machines from the manufacturers DMG Mori, Index and Hermle – including several systems with integrated loading robots, pallet changers and bar feeders. We use the latest technologies and attach great importance to the continuous training of our employees.

Our systems work fully automatically in 24/7 operation – for maximum capacity utilisation and cost-effective series production. Thanks to the seamless connection of our machines to the CAD/CAM system, we produce prototypes in the shortest possible time and realise series parts with minimum changeover effort.

CNC-milling

Using state-of-the-art CNC milling machines, we offer precise, high-quality 3- to 5-axis milling. We manufacture complex components from almost all common materials such as aluminium, copper, brass, steel, stainless steel and plastic.

Simultaneous milling on 5-axis machines means that even complex geometries can be realised efficiently and with high precision.

Thanks to flexible clamping devices, loading robots and pallet changing systems, we are optimally equipped for the production of prototypes, individual parts as well as small and large series. This enables short set-up times, stable processes and consistently high quality.

CNC-turn-milling

We use modern CNC turn-mill centres for the production of rotationally symmetrical and complex components. Our machines combine turning and milling machining in a single clamping operation, enabling cost-effective complete machining with high precision.

Thanks to the integrated milling head, sophisticated turn-mill parts can be produced efficiently – drilling and milling can be realised from almost any angle.

Our systems can be quickly retooled and are equipped with automated bar feeders that allow bars of up to Ø 100 mm to pass through. This makes them ideal for the flexible and economical production of small to medium series.

CNC turning with multiple turrets

We use CNC lathes with two to three turrets for the precise and economical production of turned parts in large quantities. In combination with twin-spindle technology, this enables parallel machining on both spindles – and therefore significantly shorter cycle times with high process stability.

Our turning centres from Mori Seiki and Index are ideal for series production in the medium to large series range. Equipped with automated bar feeders and a loading robot, they enable reliable, fully automatic 24/7 operation.

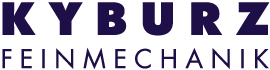

Programming

Our CNC machines are programmed using Mastercam – a powerful CAD/CAM system for milling and turning operations through to simultaneous multi-axis applications. Programming is carried out directly on the PC based on your drawing data, for example in STEP format.

In order to be able to work precisely and efficiently at all times, we use the latest versions of Mastercam. This keeps us technologically up to date and guarantees the smooth realisation of your requirements.

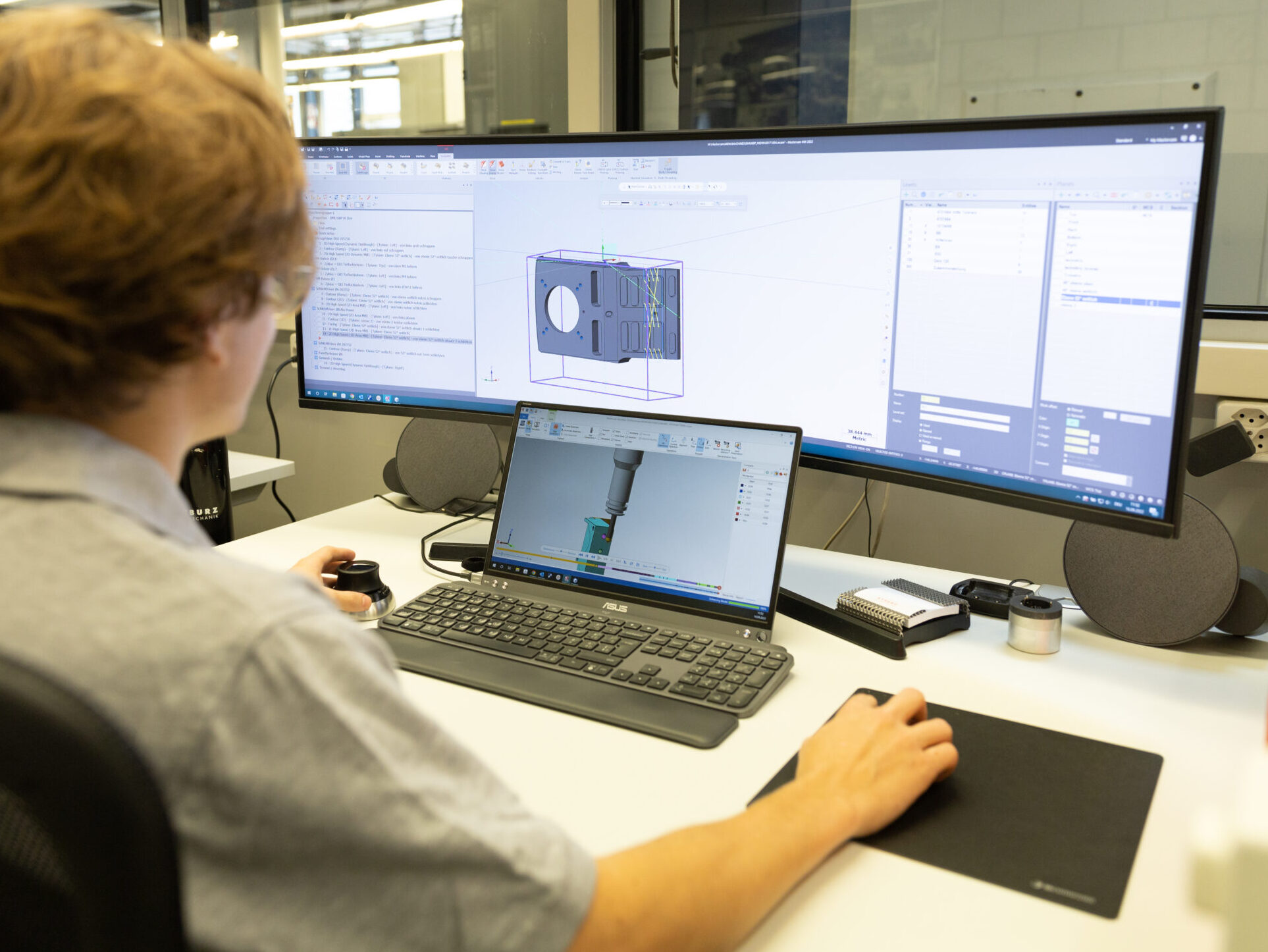

Grinding

We grind with a surface grinding machine Ziersch ZT48. The 2-axis control, an infinitely adjustable electromagnetic plate 400 x 800 mm and a Borazon disc allow us to grind even with hardened parts.

Laser engraving

Laser engraving is possible at any time. This means we can also laser mark the parts as required. Both individual components and large batch sizes can be labelled with laser marking for complete traceability, brand communication or functional markings.

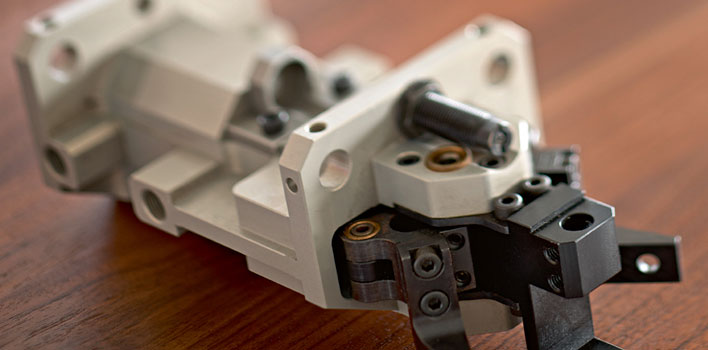

Assembling

Ready-to-assemble precision parts and assemblies

We offer our customers the entire technical process chain. From purchasing, production and assembly to surface finishing with reliable subcontractors. This applies to complex prototypes, individual parts, series and assemblies with high precision and consistent quality.